PIPESTRESS - Class 1 piping analysis ( fatigue )

Class 1 piping

![]() Connected directly to the nuclear reactor (= primary loop)

Connected directly to the nuclear reactor (= primary loop)

![]() Critical safety-related component

Critical safety-related component

![]() High

material, fabrication, inspection and design requirements

High

material, fabrication, inspection and design requirements

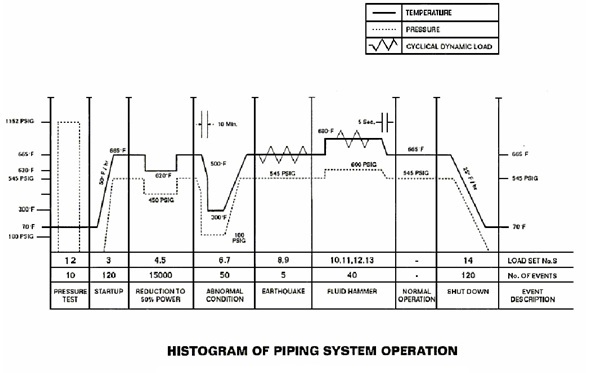

Design transients for Class 1 pipinng

Detailed stress analysis

![]() According to ASME III NB-3600, RCC-M and KTA codes

According to ASME III NB-3600, RCC-M and KTA codes

![]() Precise stress evaluation at fittings and near geometry or

material discontinuities

Precise stress evaluation at fittings and near geometry or

material discontinuities

![]() Evaluation of thermal stresses due to fluid transients

Evaluation of thermal stresses due to fluid transients

![]() Fatigue usage factor calculation

Fatigue usage factor calculation

![]() Elastic shakedown criteria

Elastic shakedown criteria

![]() Simplified elastic-plastic analysis

Simplified elastic-plastic analysis

![]() Thermal ratchet criteria

Thermal ratchet criteria

|

Radial temperature gradient ΔT1 and ΔT2 |

Axial temperature gradient Ta-Tb |

|

|

|

Environmental effects Reg. Guide 1.207

This feature was implemented in the version 3.6.2 of PIPESTRESS

Since this is a new Reg. Guide and the calculations will be necessary for licensing, continued development of rules for environmental fatigue such as a detailed calculation of strain rate is in progress in cooperation with regulatory organizations and several Licensees.

Examples of fatigue analysis reports which include the environmental factors are shown below.

Cumulative usage factor report

Fatigue analysis legend report

Fatigue analysis summary report

Stress range check report